Titanic's Cargo Gear

Titanic Research

Because of my experience on cargo ships and the fact that I teach Dry Cargo Operations to students at Maine Maritime Academy, I have long been fascinated with Titanic’s cargo gear. Chronologically she came during a transition from square rigged sailing ships to the breakbulk freighter of WW II and later fame. As it turns out her cargo gear was a little of several types of gear used at various times. She had a combination of Gin Blocks on wire spans, rotating electric cranes, and one swinging heavy lift boom. Titanic had six cargo holds, 1, 2 &3 were forward and 4, 5&6 were aft. The Gin Blocks (large diameter metal blocks hung from span wires or boom heads) on Titanic were similar to those found on the stay of a square rigged ship.

While building a 1/350 scale model of her I had noticed that there was no apparent cargo gear at #1 Hatch. This was very puzzling, and led me to research many photos of her fore deck looking for clues as to how they worked cargo in #1 Hatch. In several of the pictures I thought I saw a smudge in the rigging or was it a block hanging over the hatch? I was never certain if there was actually something there or it was the quality of the photograph. The only solid clue was the steam winch on the Fore Deck, directly aft of #1 Hatch. There were also 3 ton electric cargo winches mounted on deck at each hatch except #2 & 4. Thus each hatch except #4 could have a cargo runner from a Gin Block, in addition to the rotating cranes. You can bet that if White Star Lines went to the expense of installing a steam winch on deck there was a purpose for it. Finally I came into possession of a rigging diagram of Titanic, and there was the answer. They hung a Gin Block, rove off with a cargo runner, from a span wire, which ran from the Eyes of the ship up to the cross trees on the Fore Mast. The block was spotted directly over the hatch; the runner was hauled by the steam winch. Now a Gin Block spotted directly over the hatch has some limitations in its use. You can make the hook go up or down, but it is very hard to move a draft of cargo of any weight sideways. The solution to that I suspect lays in photographs of Berths 43 & 44 in Southampton. They show gantry mounted electric cranes on the pier. There is a photograph of this on page 86 of John P. Eaton and Charles A. Haas’ book “Titanic Triumph and Tragedy”. I suspect these cranes hoisted the draft of cargo up from the pier and either set it on the Fore Deck alongside the hatch, or they used the crane to do the whole job from pier to hold. If the draft was deposited on the Fore Deck by the crane, then a Longshoreman hooked the ship’s runner to the draft and the winch aft of #1 Hatch hoisted the draft up till it cleared the coaming then let gravity swing it sideways till it was directly under the Gin Block, at which time it was lowered into the hold. Discharging was done the same way but in reverse.

While building a 1/350 scale model of her I had noticed that there was no apparent cargo gear at #1 Hatch. This was very puzzling, and led me to research many photos of her fore deck looking for clues as to how they worked cargo in #1 Hatch. In several of the pictures I thought I saw a smudge in the rigging or was it a block hanging over the hatch? I was never certain if there was actually something there or it was the quality of the photograph. The only solid clue was the steam winch on the Fore Deck, directly aft of #1 Hatch. There were also 3 ton electric cargo winches mounted on deck at each hatch except #2 & 4. Thus each hatch except #4 could have a cargo runner from a Gin Block, in addition to the rotating cranes. You can bet that if White Star Lines went to the expense of installing a steam winch on deck there was a purpose for it. Finally I came into possession of a rigging diagram of Titanic, and there was the answer. They hung a Gin Block, rove off with a cargo runner, from a span wire, which ran from the Eyes of the ship up to the cross trees on the Fore Mast. The block was spotted directly over the hatch; the runner was hauled by the steam winch. Now a Gin Block spotted directly over the hatch has some limitations in its use. You can make the hook go up or down, but it is very hard to move a draft of cargo of any weight sideways. The solution to that I suspect lays in photographs of Berths 43 & 44 in Southampton. They show gantry mounted electric cranes on the pier. There is a photograph of this on page 86 of John P. Eaton and Charles A. Haas’ book “Titanic Triumph and Tragedy”. I suspect these cranes hoisted the draft of cargo up from the pier and either set it on the Fore Deck alongside the hatch, or they used the crane to do the whole job from pier to hold. If the draft was deposited on the Fore Deck by the crane, then a Longshoreman hooked the ship’s runner to the draft and the winch aft of #1 Hatch hoisted the draft up till it cleared the coaming then let gravity swing it sideways till it was directly under the Gin Block, at which time it was lowered into the hold. Discharging was done the same way but in reverse.

In New York I believe, based on my own experience, that they married the ship’s runner to a House Fall from the pier. Thus they had two winches and runners working so they could hoist the draft up out of the hold or off the pier apron then, Burton the draft athwartship and lower away. According to the Rigging Plan there could be similar Gin Blocks on stays rigged at each hold except #4.

Mounted on the after side of the Fore Mast was a single Heavy Lift (Jumbo) Boom. It was primarily to service #2 Hold. Those books on Titanic that address the subject of her cargo gear usually specify that this boom was for loading/discharging automobiles in #2 Hold, however it looks to me as though it could also serve #3 Hold. To use it would have required four winches, one to run the topping lift (Vertical Position of boom), and another to control the cargo hook, the last two to control the guys (Horizontal Position of Boom). These winches were clustered around the base of the Fore Mast, and would also have served the Gin Block that could be rigged there. It would probably take about an hour to rig or unrig the boom, rather time consuming.

Mounted on the after side of the Fore Mast was a single Heavy Lift (Jumbo) Boom. It was primarily to service #2 Hold. Those books on Titanic that address the subject of her cargo gear usually specify that this boom was for loading/discharging automobiles in #2 Hold, however it looks to me as though it could also serve #3 Hold. To use it would have required four winches, one to run the topping lift (Vertical Position of boom), and another to control the cargo hook, the last two to control the guys (Horizontal Position of Boom). These winches were clustered around the base of the Fore Mast, and would also have served the Gin Block that could be rigged there. It would probably take about an hour to rig or unrig the boom, rather time consuming.

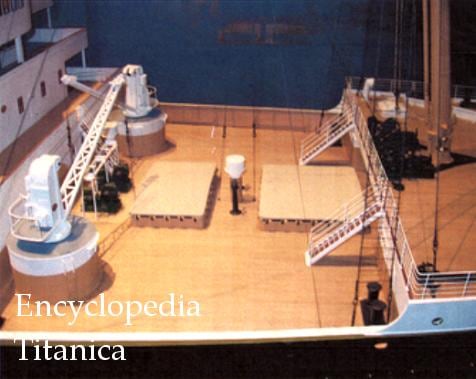

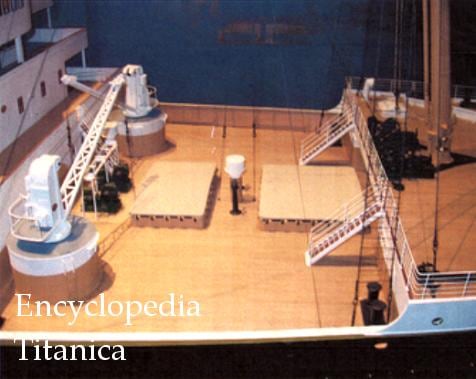

Further, there were eight rotating electric cranes built by Stothert and Pitt, Ltd. They served holds #3, #4, #5, and #6. The two cranes at #4 Hold were 30 cwt, ( 1.5 Ton capacity) the others were 50 cwt, (2.5 Ton capacity). To convert cwt (hundred weight) to tons, Webster’s Dictionary advises to multiply the cwt by 112 Lbs if in U. K. and by 100 Lbs if in the U.S.A. then divide by 2240Lbs per Long Ton. These cranes were rigged in pairs, one to port the other to starb’d, that way one could always plumb the pier and the hold regardless which side to they were berthed.

Further, there were eight rotating electric cranes built by Stothert and Pitt, Ltd. They served holds #3, #4, #5, and #6. The two cranes at #4 Hold were 30 cwt, ( 1.5 Ton capacity) the others were 50 cwt, (2.5 Ton capacity). To convert cwt (hundred weight) to tons, Webster’s Dictionary advises to multiply the cwt by 112 Lbs if in U. K. and by 100 Lbs if in the U.S.A. then divide by 2240Lbs per Long Ton. These cranes were rigged in pairs, one to port the other to starb’d, that way one could always plumb the pier and the hold regardless which side to they were berthed.

So we see that just as Titanic’s engines transitioned from reciprocating to turbine so to her cargo gear was a transition to a more modern type gear.

In New York I believe, based on my own experience, that they married the ship’s runner to a House Fall from the pier. Thus they had two winches and runners working so they could hoist the draft up out of the hold or off the pier apron then, Burton the draft athwartship and lower away. According to the Rigging Plan there could be similar Gin Blocks on stays rigged at each hold except #4.

So we see that just as Titanic’s engines transitioned from reciprocating to turbine so to her cargo gear was a transition to a more modern type gear.

Bibliography

Bonsall, Thomas. Titanic. New York: Gallery Books, 1987.

McCluskie, Tom. Anatomy of the Titanic. San Diego, CA: Thunder Bay Press, 1998.

Ocean Liners of the Past, Olympic and Titanic. Cambridge: Patrick Stephens Ltd. 1983.

Photographs by Charles Weeks. Taken at Mystic Aquarium, of a 1:48 scale model of R.M.S. Titanic, by Fine Arts Models.

Text and Photographs © Charles B. Weeks Jr 2004

No comments:

Post a Comment